MOLDING WHITE PAPERS, APPLICATION NOTES, & CASE STUDIES

MOLDING VIDEOS, WEBINARS, AND PODCASTS

-

In this webinar, we delve into how conventional plastics behave under extreme shear stress and its real-world impact on micro medical product design. Gain insights to make informed material choices.

-

Utilizing Medbio’s Prototype-Plus process, the same tool that provides prototype samples for testing and validation can be used for the initial production run.

-

Take a look inside our ISO 13485 certified Orchard Park, New York locations featuring two full-service facilities: one dedicated to silicone and the other for thermoplastics injection molding.

-

Join us for a tour of the Medbio headquarters on our Grand Rapids campus, featuring multiple ISO 13485-certified facilities totaling 90,000 square feet.

-

Take a tour of Medbio's ISO13485 certified Clinton Township location's two facilities with approximately 55,000 sq. ft. of manufacturing space which house injection molding, in-house mold design, and tooling construction.

-

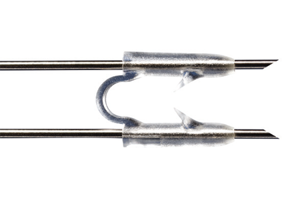

This webinar by Xcentric discusses the addition of undercuts and side action complexities to molding applications without sacrificing speed to market.

MOLDING NEWS

-

When faced with "no-quote" responses in micro molding, engineers should rethink assumptions and collaborate with Accumold's innovation lab for transformative solutions.

-

As you delve into micro injection molding, aligning with a proficient subcontract manufacturer proves essential for seamless product development, from conception to high-volume production.

-

Explore the future of micro manufacturing, where the convergence of micro molding and 3D printing promises to redefine what's possible in the creation of intricate, high-quality components.

-

Learn how the critical properties of micro molded components - such as strength, flexibility, and thermal resistance - are shaped by the intricacies of material selection.

-

Discover how leaders in micro molding for medical devices are pushing boundaries to create innovative solutions that enhance patient care and quality of life.

-

CEO Gary Hulecki reflects on how MTD lives into one of their core values, Be a Team, from meetings with customers to magazine interviews to profit-sharing.

-

Explore the world of silicone micro molding - where engineers navigate complex challenges in handling unique properties, like addressing static cling and inspection difficulties.

-

In the realm of micro molding, choosing the perfect partner requires careful inquiry. By asking these vital questions, you can foster a partnership for mutual success.